A day in CEE’s construction materials lab

By: Julia Davis

October 27, 2025

Photos: Dennis Wise/University of Washington

Top image: Broken concrete cylinders pile up after testing. Students sort through the pieces to find out how each sample failed and what that says about their mix.

Undergrads mix, test and break concrete to learn how materials behave in the real world.

In CEE’s Construction Materials class, one of the department’s foundational undergraduate courses, students learn about the properties and performance of materials used in heavy construction, such as cement and concrete. The course equips students with knowledge to assess material and guide selections for construction projects, a key aspect of construction engineering. It’s also one of the first truly hands-on courses for civil engineering majors. Taught by Associate Teaching Professor Julian Yamaura, the class pairs focused lectures with weekly labs where students design mixes, follow American Society for Testing and Materials (ASTM) standards, and determine how choices in ingredients, proportioning and curing change performance.

“We go into this assuming none of our students have any idea what concrete even is,” says Yamaura, who is the Tom and Marilyn Draeger / Beavers Charitable Trust Term Faculty Fellow. “The lab is where it becomes exciting because they get to apply all their lecture knowledge, and you can see it just click.”

“The lab is where it becomes exciting because they get to apply all their lecture knowledge, and you can see it just click.”

On this day in the lab, teams made two very different concretes: a high-strength mix and a pervious mix that lets stormwater and other sources of runoff drain through while still providing some strength. After testing, students “read” the fracture surfaces together to understand how their ingredient ratios and curing steps affected performance.

The class also serves as practice for teaching assistants, who lead small groups through mixing, testing and post-test reviews.

“It’s a great opportunity for teaching assistants to develop their own teaching and communication skills while also strengthening their technical mastery of the subject,” Yamaura says.

By the end of the quarter, students can explain not just what a mix did but why it failed or held up — in the same terms used on industry projects.

“The students get a connection to the materials and how things get built in industry,” Yamaura says. “It inspires many students to lean into construction engineering and appreciate not only the design-related activities but also the hands-on nature of fieldwork and working in teams.”

Left: Students use a hydraulic press to crush concrete cylinders; results show the pressure at failure (psi). Top right: TA Grace Collins unwraps a just-tested cylinder in front of students. Bottom right: A fractured face shows aggregate and paste bonding, which serve as clues that teams use to fine-tune ratios and curing.

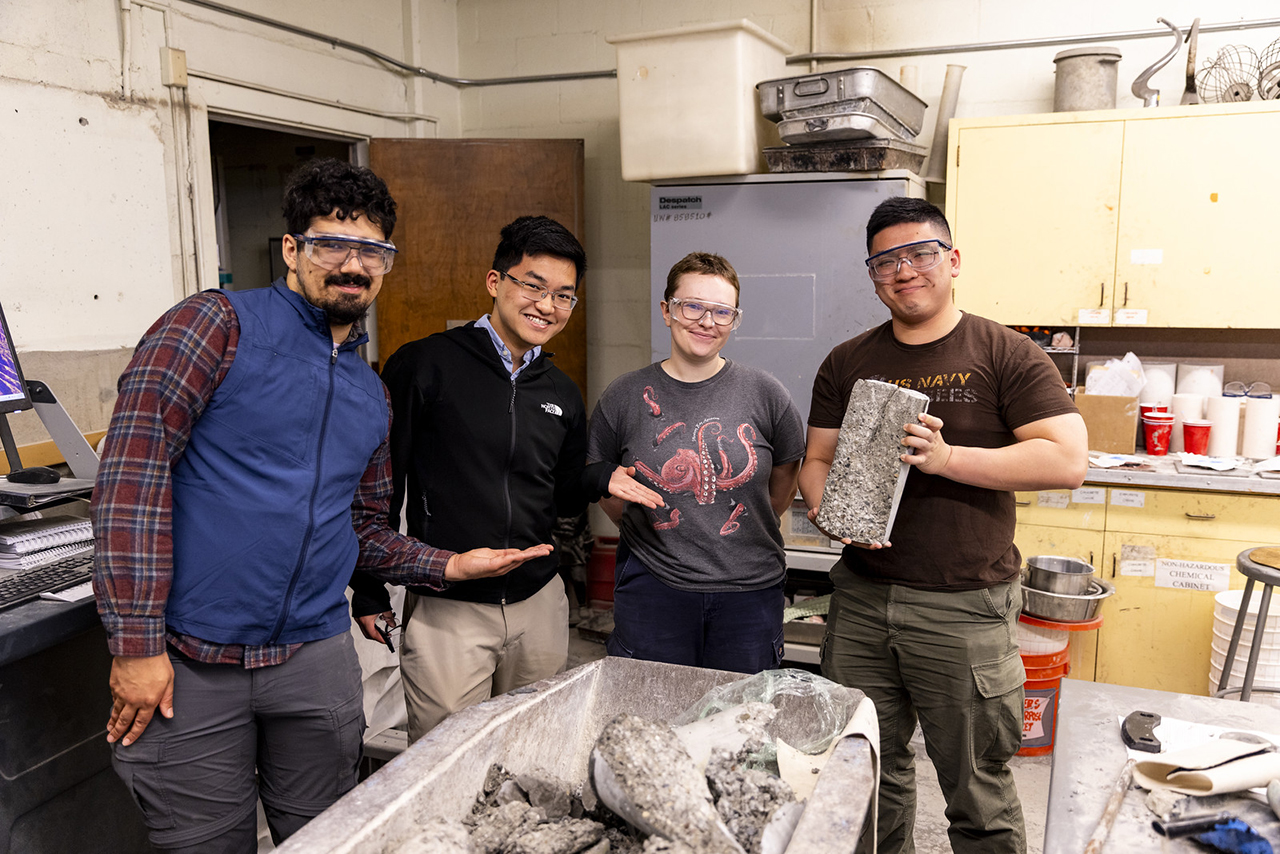

Left: Reading the cracks: Associate Teaching Professor Julian Yamaura points out fracture lines on a team’s cylinder. These patterns offer clues about compaction, air content and how the sample was cured.Right: A successful lab test: Students show off their cylinders after a full round of testing.