The Large-Scale Structural Engineering Testing Laboratory's versatile facility and equipment is used for a broad range of experiments that contribute to advances in structural engineering.

On average, between 2 and 6 research projects utilize the Large-Scale Structural Engineering Testing Laboratory at any given time. Research projects are funded by organizations such as the National Science Foundation, National Cooperative Highway Research Program, Federal Highway Administration, Washington State Department of Transportation, California Department of Transportation, U.S. Army and local county highway and public works departments. Below are several recent examples of experiments conducted in the Large-Scale Structural Engineering Testing Laboratory, which highlight basic test configurations.

Example applications

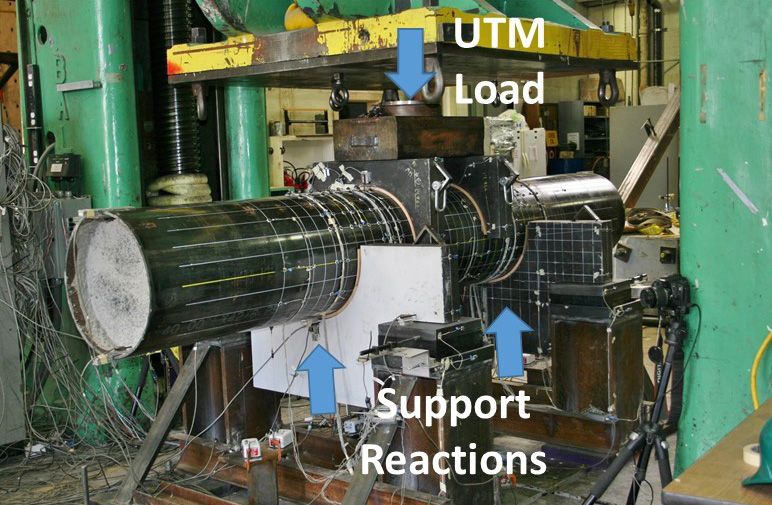

Shear Strength of Concrete Filled Steel Tubes

Equipment and Instrumentation Used: 2,400 kip UTM, 120 channels of strain gauges and potentiometers, NDI OptoTrak and National Instruments data acquisition

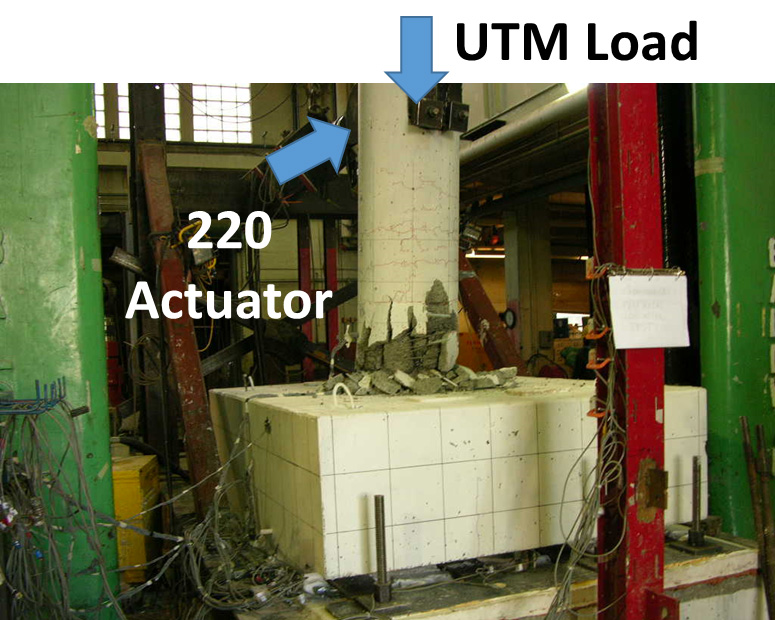

Seismic Performance of Bridge Columns and Piles (Several Projects)

Equipment and Instrumentation Used: 2,400 kip UTM, 220 kip actuator, 60+ channels of strain gauges and potentiometers, NDI OptoTrak and National Instruments data acquisition

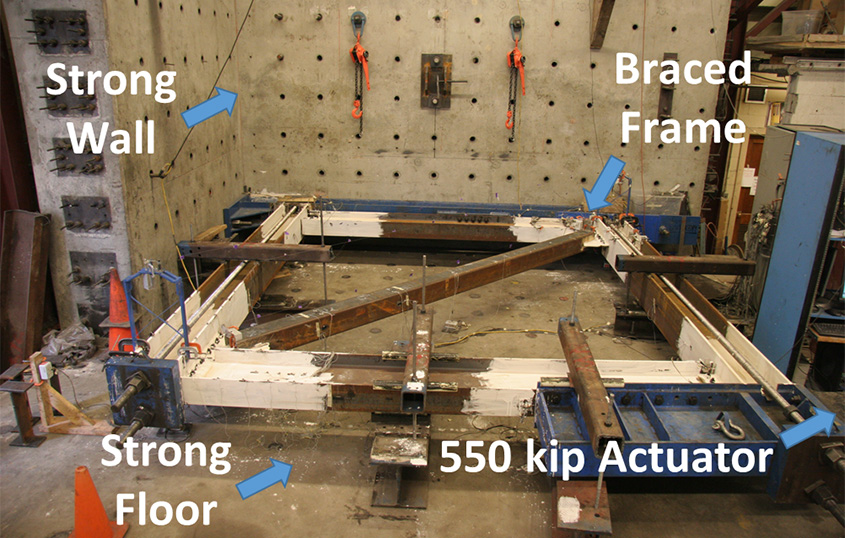

Seismic Performance of Steel Braced Frames (Several Projects)

Equipment and Instrumentation Used: Strong wall, strong floor, 550 kip actuator, MTS FlexTest controller, 120 channels of strain gauges and potentiometers, NDI OptoTrak and National Instruments data acquisition

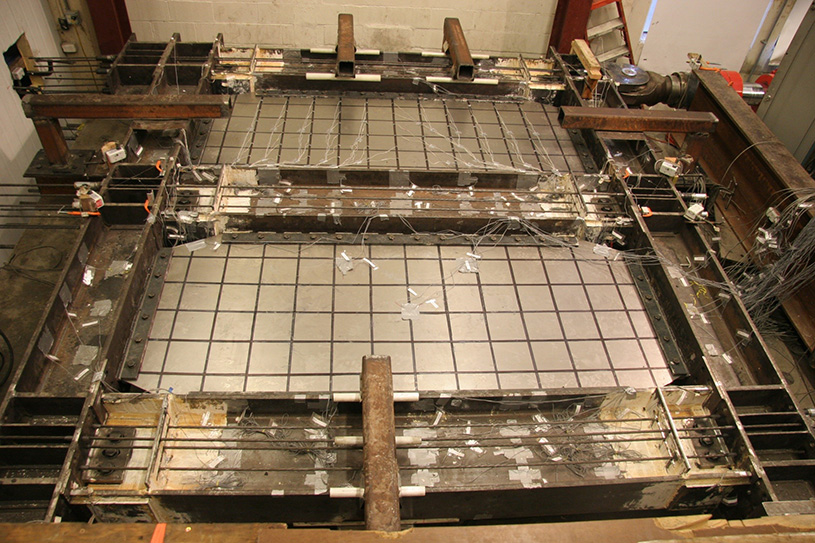

Seismic Performance of Self-Centering Steel Plate Shear Walls

Equipment and Instrumentation Used: Custom built reconfigurable reaction blocks (permanent equipment), 450 kip ±10 inch actuator, MTS Flex Test Controller, custom-built load cells for post-tensioning strands, 100+ channels of strain gauges and potentiometers

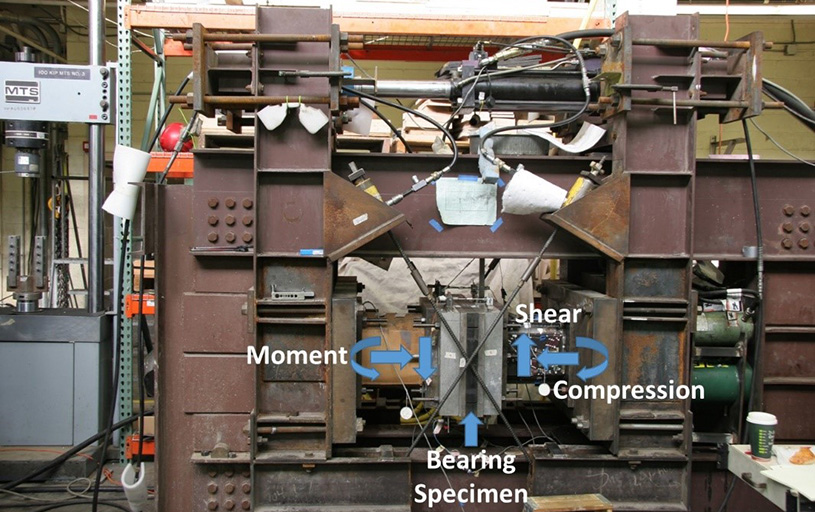

Behavior of Bridge Bearings Under Combined Loading (Several Projects)

Equipment and Instrumentation Used: Custom fabricated load frame (permanent equipment), 55 kip ±10 inch stroke actuator, MTS 442 Controller, large capacity multiaxial load cells, 10+ channels of strain gauges and potentiometers and National Instruments data acquisition